PVC cards are plastic cards, like credit and debit cards. They can be used to make purchases in stores or online, can be used for identity cards, membership cards, the list goes on!

PVC cards are plastic cards that have polyvinyl chloride (PVC) film laminated to both sides of the card. They are typically used for identification purposes but can be made with other materials as well.

The PVC material is used to make the cards more durable and scratch-resistant than traditional paper or plastic cards. These types of cards can be produced in any color, which allows for customization.

There are many different sizes and thicknesses of PVC cards available so you can choose the best one for your needs. Some companies also offer UV coating on their products, which will protect against fading and cracking over time.

The process of making PVC cards

The process of making and printing PVC cards is relatively simple but does require some time and effort. PVC cards are a surprisingly complex material. PVC cards are made of at least a few thin layers and are not simple plastic cards. The material type and quality used in production all affect how strong the final product turns out to be.

The making of a PVC card consists of starting by cutting a sheet of PVC to the appropriate size. The color is then added to one side, and text, logos, or graphics are printed on the other. The cards are then run through an oven for 10-12 minutes at 350 degrees Fahrenheit. This helps seal in the color and ink, as well as cross-linking the plastic molecules together, which makes them more durable than regular plastic cards.

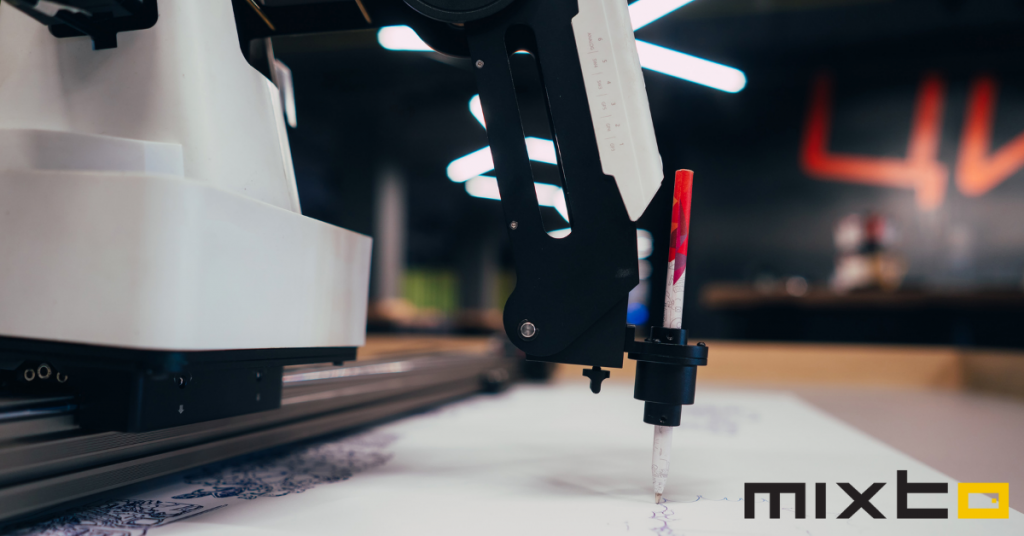

Printing PVC cards is a process that uses heat and pressure to create an image on a plastic substrate. The printing process begins with the transfer of the image file to the printer. The printer then prints the image onto a sheet of thermal paper. The thermal paper is then fed into the printer’s laminating unit, where it is fused to the PVC card.

Once the card has been laminated, it is cut to size and punched with holes for use in a variety of applications. In addition to durability, this manufacturing process also creates a water-resistant finish that prevents liquids from seeping into the card’s surface.

When it comes to printing, there are a few different ways that PVC cards can be printed. The most common way is using a digital printer. This type of printer prints the image directly onto the card surface. Some printers also use ribbons for printing and are typically used for printing higher volumes of cards.

Lastly, there are offset printers which are used for printing large quantities of cards. Cards printed using this method have a higher quality finish than those printed with other methods.

There are many different ways to make PVC cards. If you are looking for personalized PVC cards, Mixto is happy to help you. Our team at Mixto specializes in high-quality PVC card printing, and we can help you get your custom design printed on a durable plastic material that will last for years. Whether you need 500 cards or 10,000, our experts have the knowledge and experience to bring your vision to life!

We also offer custom designs and printing options so you can find something that fits your brand identity perfectly. For information about how we create such high-quality PVC cards, contact us today!